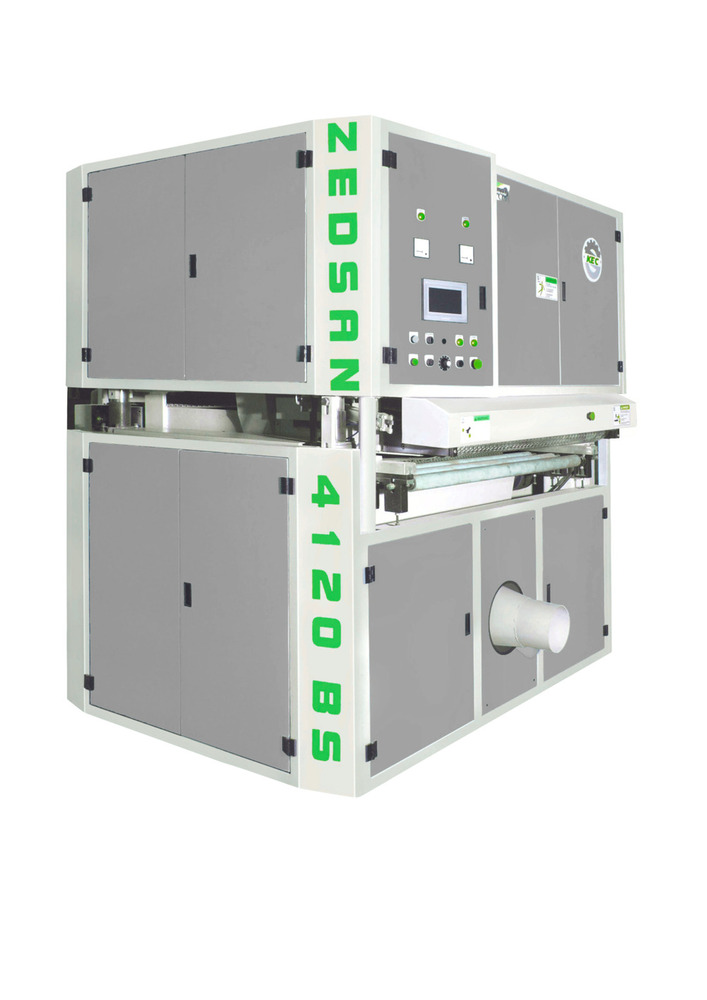

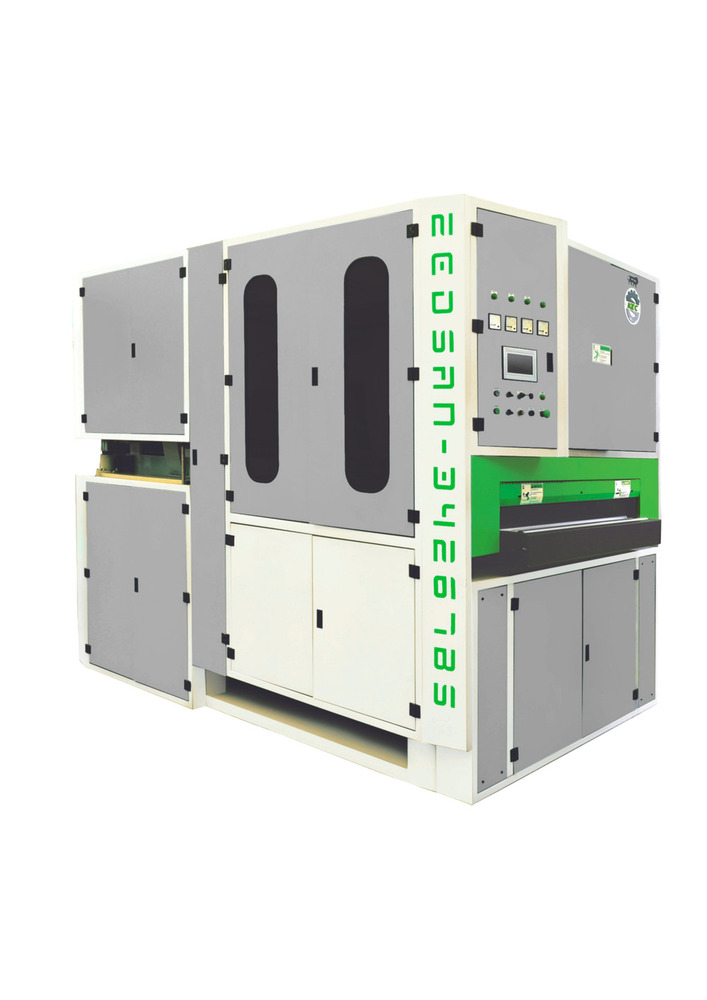

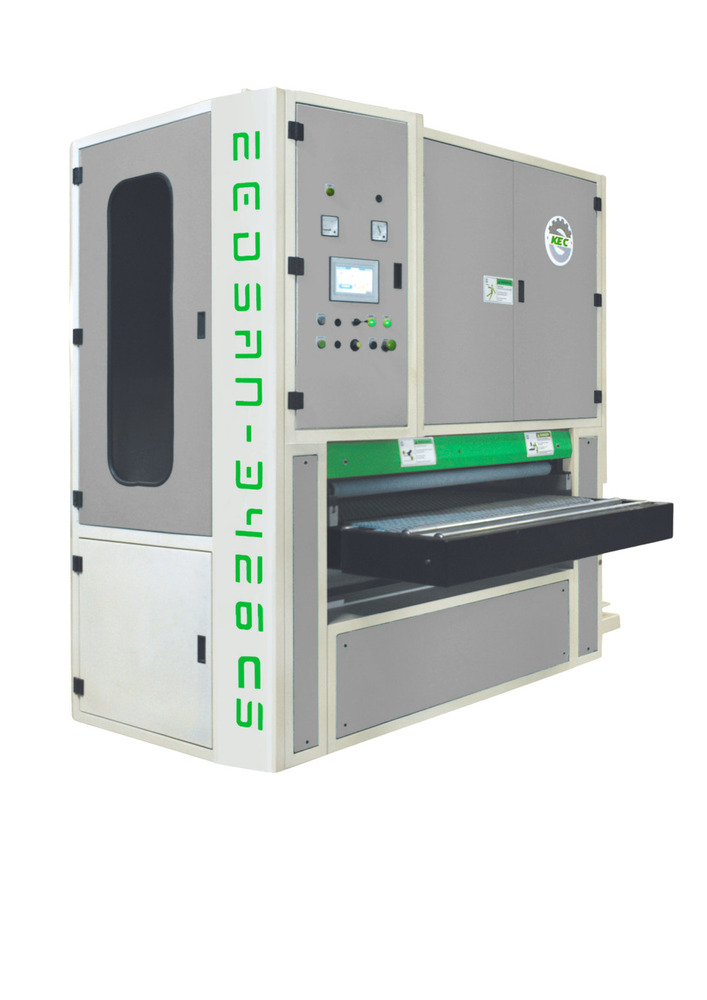

Double Head Wide Belt Sanding Machine - Bottom

Double Head Wide Belt Sanding Machine - Bottom Specification

- Computerized

- Yes

- Automatic Grade

- Automatic

- Weight

- 4200 Kilograms (kg)

- Dimension (L*W*H)

- 2100x2250x2600 Millimeter (mm)

- Color

- Green-White

- Warranty

- 1 year

Double Head Wide Belt Sanding Machine - Bottom Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 2 Units Per Month

- Delivery Time

- 30-45 Days

- Packaging Details

- Bubble Sheet & wooden box packing.

- Main Domestic Market

- All India

- Certifications

- An ISO 9001:2015 Certified

About Double Head Wide Belt Sanding Machine - Bottom

This machine has the following features-- Used in synchronization with Top Sanding machine.

- Perfect sanding results on the uneven thickness

- Highly gloss sanding results, as in top sanding machine

- Fast production, as both side sanding is achieved in one pass

- Changeable results, by easy configuration settings.

Very useful for-

- Production units with more than 3000 sheets per day production.

- Commercial sanding

- Veneer Sanding

- MR Sanding

- Veneer Faced Flush Doors

Advanced Computerized Control

The integrated computer system facilitates intuitive operations, automating adjustments and optimizing the sanding process for different materials. This ensures high precision and reduces manual intervention, saving both time and labor costs.

Heavy-Duty Construction for Industrial Use

With a substantial weight of 4200 kg and a sturdy build, this wide belt sanding machine offers stability during operation. Its sizable dimensions allow for the processing of large panels, making it an excellent choice for industrial-scale production.

FAQs of Double Head Wide Belt Sanding Machine - Bottom:

Q: How does the computerized feature enhance the operation of this sanding machine?

A: The computerized feature automates adjustments during the sanding process, enabling operators to set parameters easily. It increases precision, reduces manual errors, and improves overall operational efficiency.Q: What types of materials can be processed using this Double Head Wide Belt Sanding Machine?

A: This machine is suitable for sanding a wide range of materials, including wood, MDF, plywood, and various metal surfaces, making it versatile for different manufacturing requirements.Q: When is the ideal stage to use this machine in a production workflow?

A: The Double Head Wide Belt Sanding Machine is best used after initial cutting and shaping, serving as a finishing process to achieve smooth and even surfaces before assembly or coating.Q: Where can this machine be installed for optimal productivity?

A: This sanding machine is designed for integration into manufacturing plants, woodworking workshops, or metalworking facilities where stable flooring and sufficient space (2100x2250x2600 mm) are available.Q: What is the typical usage process for operating this sanding machine?

A: Operators load the workpiece onto the conveyor, select preset parameters via the computerized panel, and initiate the process. The automatic system manages feed rate and sanding intensity for consistent finishing.Q: What are the main benefits of choosing this model for your production line?

A: Key benefits include superior surface finish, automated operation reducing manual workload, high capacity for large panels, durability, and the assurance of a one-year warranty for reliable after-sales support.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plywood Sander Machines Category

Hardwood Calibrating & Sanding Machine

Minimum Order Quantity : 1 Unit

Color : Multicolor

Dimension (L*W*H) : 4200*2050*1900 Millimeter (mm)

Automatic Grade : Automatic

Computerized : Yes

Warranty : Yes

Heavy Duty Both Side Sanding Machine

Minimum Order Quantity : 1 Unit

Color : Multicolor

Dimension (L*W*H) : 2250x3350x2700 Millimeter (mm)

Automatic Grade : Automatic

Computerized : No

Warranty : Yes

Single Combi Head Sanding Machine

Minimum Order Quantity : 1 Unit

Color : Multicolor

Dimension (L*W*H) : 2150x2240x2200 Millimeter (mm)

Automatic Grade : Automatic

Computerized : No

Warranty : Yes

Heavy Duty Laminate Sanding Machine

Minimum Order Quantity : 1 Unit

Color : Multicolor

Dimension (L*W*H) : 1500x2840x2300 Millimeter (mm)

Automatic Grade : Automatic

Computerized : No

Warranty : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free