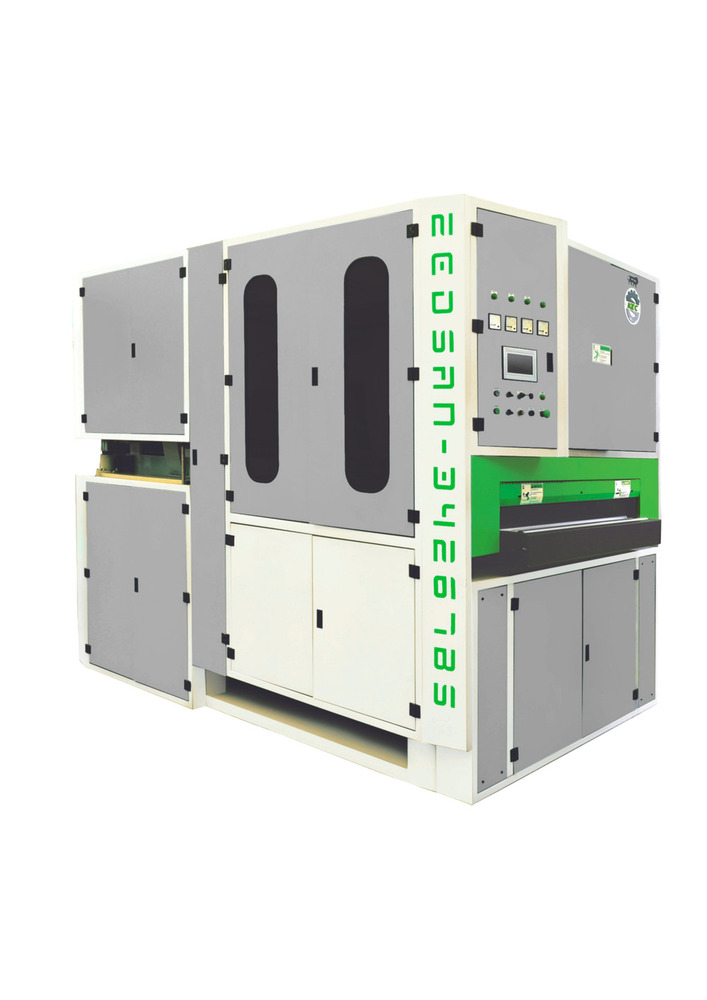

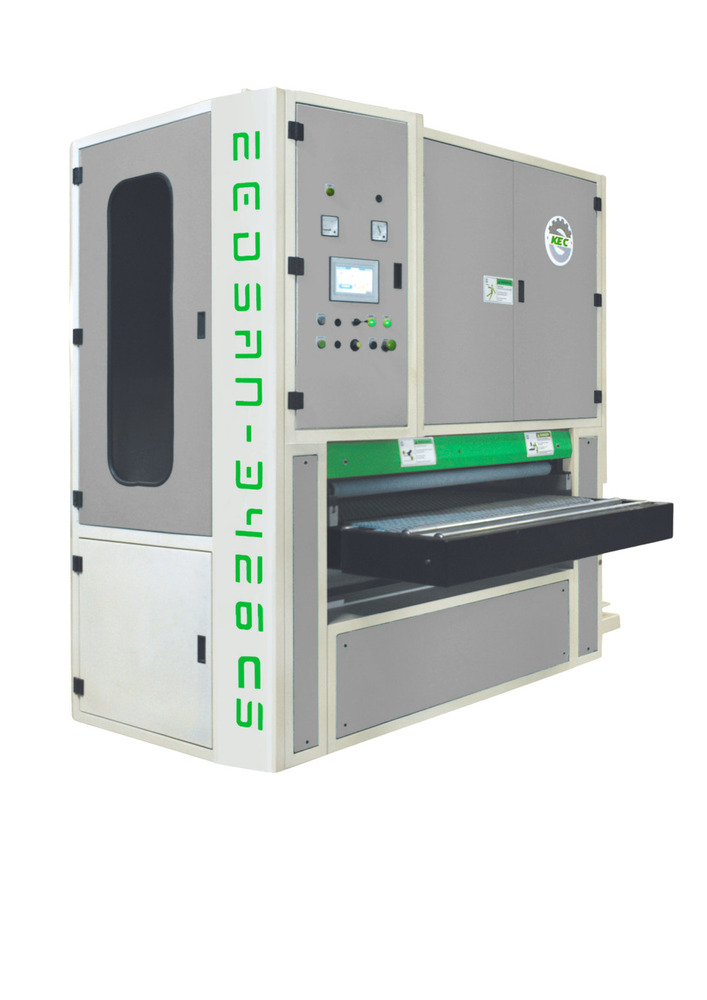

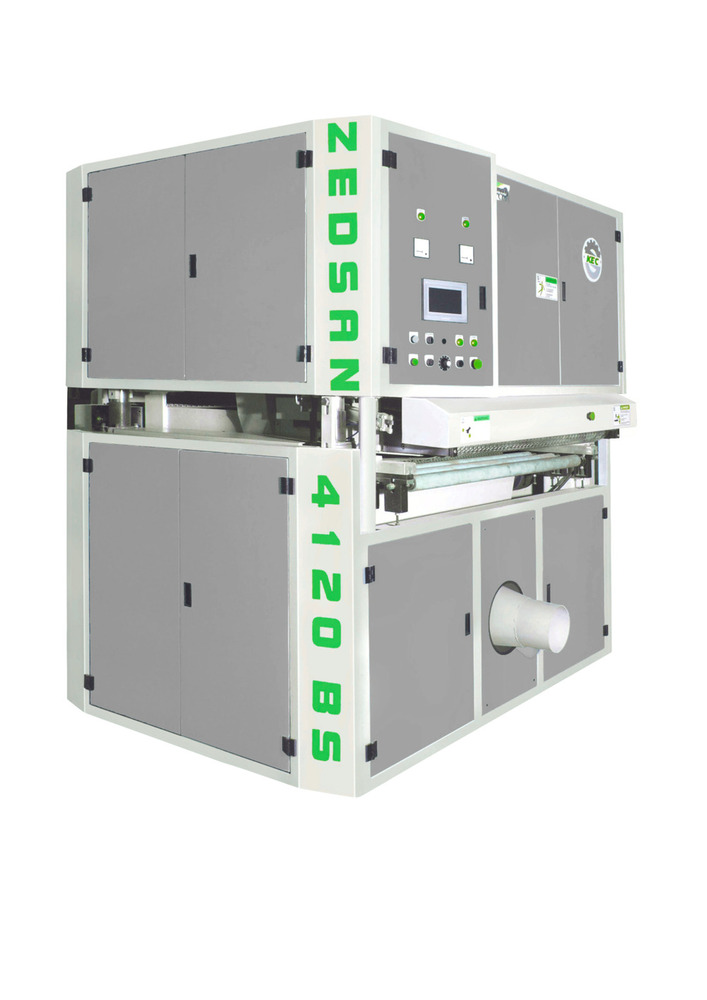

Triple Head Calibrating And Sanding Machine

Triple Head Calibrating And Sanding Machine Specification

- Type

- Triple Head Calibrating And Sanding Machine

- Material

- Mild Steel

- Computerized

- No

- Automatic Grade

- Automatic

- Power

- 20 Horsepower (HP)

- Voltage

- 240 Volt (v)

- Color

- Multicolor

- Warranty

- Yes

Triple Head Calibrating And Sanding Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

- Certifications

- An ISO 9001:2015 certified

About Triple Head Calibrating And Sanding Machine

Three heads of this machine are designed in such a way that the first head is used for calibration, the second head for sanding, and the third head for polishing. While calibration, 1st head is operational, and while sanding, the second and third head is operational.

This machine is a complete solution for making calibrated ply with ultimate sanding results.

Advanced Triple Head System

The machine's triple head design ensures both calibration and fine sanding in a single run. This setup delivers uniform surface quality, increases production speed, and is especially suitable for high-volume manufacturing environments. The heads can handle various wood thicknesses, resulting in smoother and more precise surfaces.

Robust Construction and Dimensions

Built from high-grade mild steel, this equipment provides stability and long operational life. Its dimensions (3100x2240x2300 mm) and substantial weight make it well-suited for stationary use in factories and industrial plants, ensuring minimal vibration and accurate output during high-load processing.

Automatic and Efficient Operations

With an automatic grade and computer-free operation, this machine allows easy setup and control, streamlining your workflow. The 20 HP motor and 240V power source deliver consistent power, optimizing efficiency for large-scale woodworking operations and reducing manual labor requirements.

FAQ's of Triple Head Calibrating And Sanding Machine:

Q: How does the Triple Head Calibrating and Sanding Machine improve sanding efficiency?

A: This machine incorporates three sanding heads, enabling it to calibrate and finish the surface in one continuous process. This increases operational speed, ensures uniform sanding results, and minimizes manual handling.Q: What types of industries benefit most from this machine?

A: Exporters, manufacturers, suppliers, and traders involved in wood processing or panel production in India will benefit from this machine's high capacity and precision.Q: When should I consider using a triple head machine instead of a single or double head unit?

A: A triple head calibrating and sanding machine is recommended when you need high throughput, consistent surface quality, and want to combine multiple processing steps to save time in industrial-scale operations.Q: Where is the optimal place to install this sanding machine?

A: Due to its weight (5700 kg) and size (3100x2240x2300 mm), the machine should be installed on a solid, level factory floor with sufficient space for easy access and material handling.Q: What is the benefit of the machine's automatic operation?

A: Automatic operation streamlines production, reduces manual labor, and allows for consistent quality with less operator involvement, making it ideal for continuous workflows.Q: How long is the warranty period for this machine?

A: The machine comes with a one-year warranty, covering manufacturing defects and ensuring peace of mind for your investment.Q: What power requirements should I be aware of before installation?

A: This machine operates at 240 volts and requires a compatible industrial power supply to deliver the 20 horsepower needed for efficient functioning.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plywood Sander Machines Category

Hardwood Calibrating & Sanding Machine

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Warranty : Yes

Computerized : Yes

Color : Multicolor

Type : Hardwood Calibrating & Sanding Machine

Heavy Duty Both Side Sanding Machine

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Warranty : Yes

Computerized : No

Color : Multicolor

Type : Heavy Duty Both Side Sanding Machine

Single Combi Head Sanding Machine

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Warranty : Yes

Computerized : No

Color : Multicolor

Type : Single Combi Head Sanding Machine

Double Head Wide Belt Sanding Machine - Bottom

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Warranty : 1 year

Computerized : Yes

Color : GreenWhite

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free