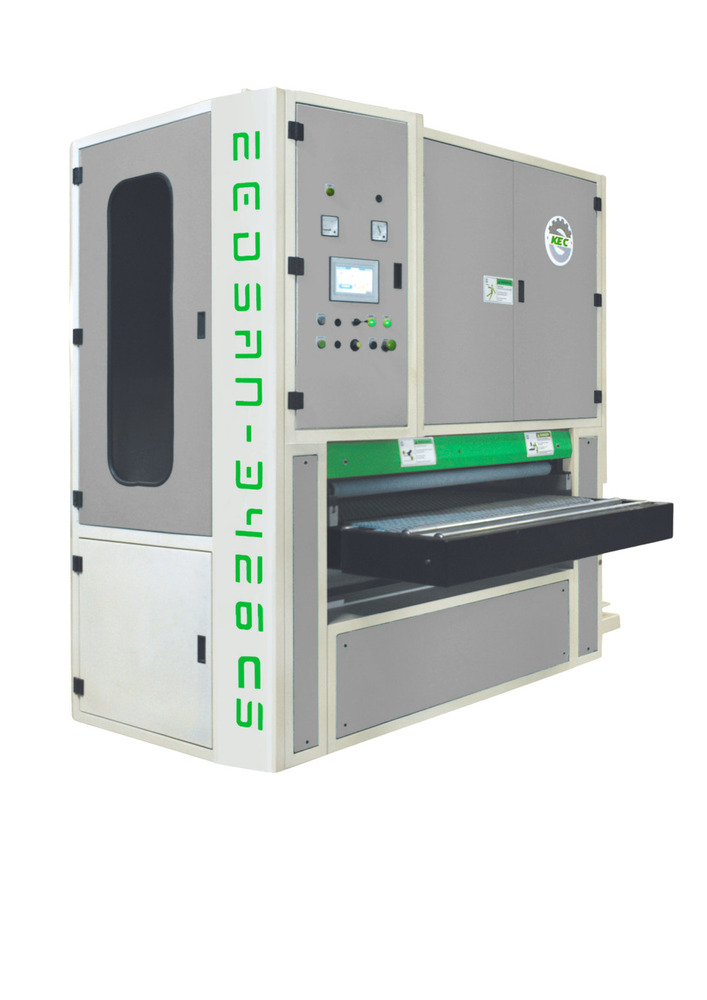

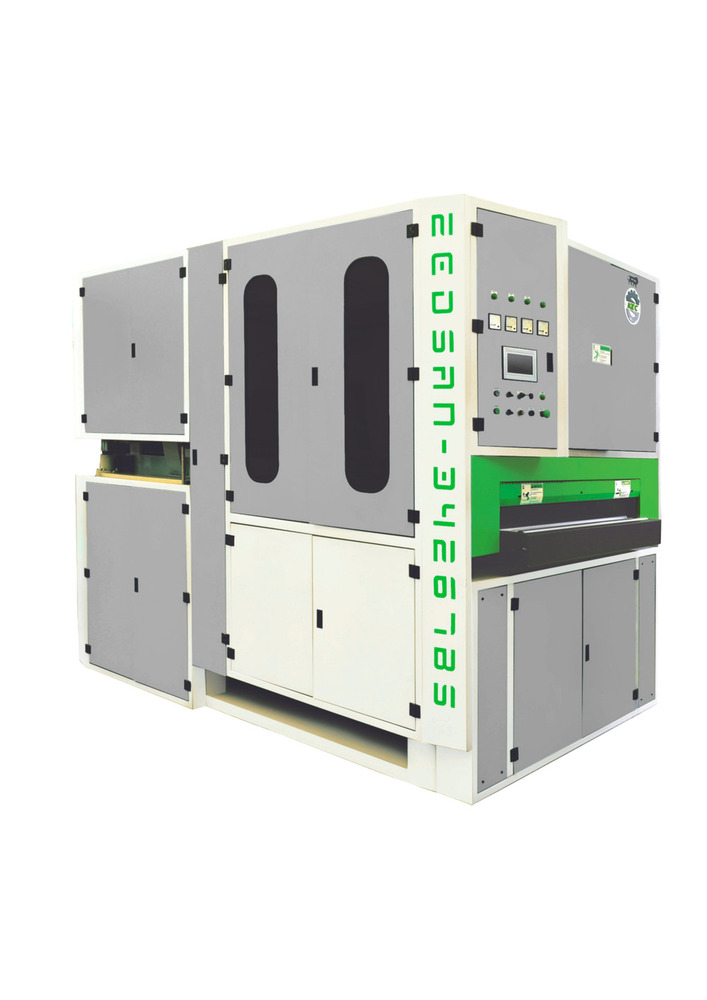

Hardwood Calibrating & Sanding Machine

Price 2200000.0 INR/ Unit

Hardwood Calibrating & Sanding Machine Specification

- Type

- Hardwood Calibrating & Sanding Machine

- Material

- Mild Steel

- Capacity

- 100 Pcs/hr

- Computerized

- Yes

- Automatic Grade

- Automatic

- Power

- 20 Horsepower (HP)

- Voltage

- 240 Volt (v)

- Filling Heads

- 6

- Air Pressure

- 5-30 mpa

- Weight

- 2900 Kilograms (kg)

- Dimension (L*W*H)

- 4200*2050*1900 Millimeter (mm)

- Color

- Multicolor

- Warranty

- Yes

Hardwood Calibrating & Sanding Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- sampla

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 2 Units Per Month

- Delivery Time

- 30 Days

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- sand and water proof solution packaging

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- An ISO 9001:2015 certified

About Hardwood Calibrating & Sanding Machine

The cutter roller brings all thickness variations in one set value by applying a minimum quantum of power. Sanding belt application on the second head converts the job into a unique look.

Precision Performance for Hardwood Processing

Engineered for accuracy, this machine optimizes hardwood surface preparation with automatic calibration and sanding capabilities. Utilizing computerized controls, it delivers uniform results across a high capacity of up to 100 pieces per hour. This vertical, automatic machine stands out in demanding production environments, providing versatile handling for large and small operations alike.

Robust Construction and Versatile Application

Constructed from durable mild steel and finished in appealing colors, the machine combines robust longevity with aesthetic versatility. The flexible size options and substantial weight ensure stability during operation. With its advanced features and high horsepower, this sanding and calibrating machine is suitable for large-scale manufacturers, exporters, and suppliers across the woodworking industry.

FAQ's of Hardwood Calibrating & Sanding Machine:

Q: How does the Hardwood Calibrating & Sanding Machine improve woodworking processes?

A: The machine streamlines surface preparation by delivering consistent calibration and sanding results automatically, which enhances quality, reduces manual labor, and increases productivity.Q: What types of hardwood workpieces can be processed with this machine?

A: It is suitable for a wide variety of hardwoods, accommodating different sizes and thicknesses due to its versatile design and adjustable calibrating settings.Q: When is it appropriate to use this machine in production?

A: This machine is ideal for use during bulk processing or when precise, uniform sanding and calibrating are needed for hardwood pieces before further finishing or assembly.Q: Where is this machine manufactured and supplied from?

A: The Hardwood Calibrating & Sanding Machine is manufactured, exported, supplied, and traded from India, providing both domestic and international availability.Q: What is the process for operating the machine?

A: Operation involves configuring the computerized controls, loading hardwood pieces, and initiating the automatic cycle. The machine then calibrates and sands each workpiece according to pre-set parameters.Q: What are the main benefits of using a computerized and automatic grade machine?

A: Computerization and automation ensure precise, repeatable results, minimize operator error, reduce downtime, and support higher throughput, boosting overall efficiency and product quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plywood Sander Machines Category

Single Combi Head Sanding Machine

Minimum Order Quantity : 1 Unit

Computerized : No

Color : Multicolor

Warranty : Yes

Automatic Grade : Automatic

Voltage : 240 Volt (v)

Heavy Duty Both Side Sanding Machine

Minimum Order Quantity : 1 Unit

Computerized : No

Color : Multicolor

Warranty : Yes

Automatic Grade : Automatic

Voltage : 240 Volt (v)

Heavy Duty Laminate Sanding Machine

Minimum Order Quantity : 1 Unit

Computerized : No

Color : Multicolor

Warranty : Yes

Automatic Grade : Automatic

Voltage : 240 Volt (v)

Triple Head Calibrating And Sanding Machine

Minimum Order Quantity : 1 Unit

Computerized : No

Color : Multicolor

Warranty : Yes

Automatic Grade : Automatic

Voltage : 240 Volt (v)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS