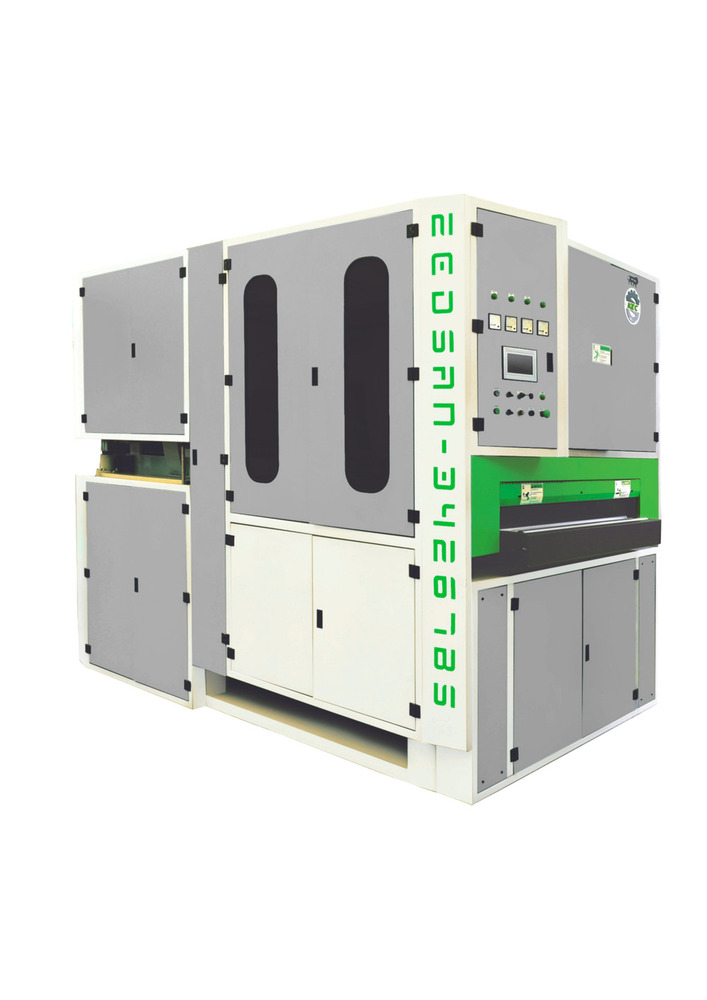

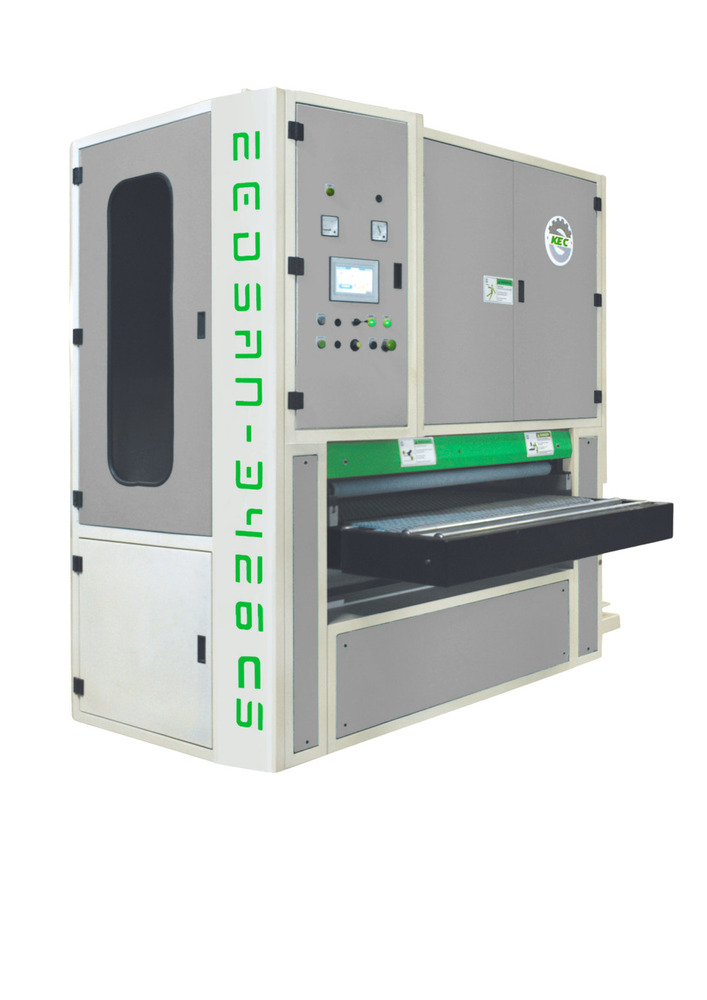

Heavy Duty Laminate Sanding Machine

Heavy Duty Laminate Sanding Machine Specification

- Type

- Heavy Duty Laminate Sanding Machine

- Material

- Mild Steel

- Computerized

- No

- Automatic Grade

- Automatic

- Power

- 20 Horsepower (HP)

- Voltage

- 240 Volt (v)

- Color

- Multicolor

- Warranty

- Yes

Heavy Duty Laminate Sanding Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

- Certifications

- An ISO 9001:2015 certified

About Heavy Duty Laminate Sanding Machine

The Heavy Duty Laminate Sanding Machine covers all features as a light-duty machine, with an additional advantage of higher capacity of the main motor to carry high sanding load to achieve higher production. All settings and adjustments are designed for the best user-friendly concept.Engineered for High-Volume Sanding

Crafted with a mild steel frame for durability, this heavy-duty sanding machine excels in high-output environments. Its substantial build accommodates demanding laminate processing, ensuring precise surface finishing even under continuous operation. The vertical structure maximizes workflow efficiency by providing easy access and straightforward loading of panels, making it ideal for large industrial facilities and workshop floors alike.

Automated Performance with Reliable Control

The machine offers both automatic and semi-automatic operational modes, giving users flexibility to tailor processes to specific needs. Powered by a robust 20 HP electric motor and operating on a 240V supply, it can efficiently handle even the most challenging sanding applications. Its user-friendly interface and straightforward controls enable streamlined operation, minimizing downtime and increasing productivity.

FAQ's of Heavy Duty Laminate Sanding Machine:

Q: How does the Heavy Duty Laminate Sanding Machine improve sanding efficiency?

A: The machine's powerful 20 HP motor, vertical design, and automatic features ensure uniform sanding across large laminate panels, significantly reducing manual effort and processing time while delivering consistent, high-quality finishes.Q: What types of materials can be processed using this sanding machine?

A: This machine is primarily designed for laminate sheets and panels. Its robust construction allows it to handle varying laminate thicknesses, making it suitable for a range of industrial finishing applications.Q: Where is this machine manufactured and supplied from?

A: This heavy-duty sanding machine is manufactured and supplied from India. It is available for purchase and export by manufacturers, suppliers, and traders operating across domestic and international markets.Q: What is the installation and setup process like?

A: The installation involves placing the 6,200-kilogram machine in a prepared space with adequate floor support, connecting it to a 240V electrical supply, and calibrating the sanding controls. Professional setup assistance is usually recommended to ensure optimal performance.Q: How is routine maintenance handled for this sanding machine?

A: Routine maintenance includes checking for wear on sanding components, lubricating moving parts, and ensuring all safety and electrical systems are functioning correctly. Regular maintenance increases machine longevity and operational efficiency.Q: What are the primary benefits of using a computerized or non-computerized sanding machine?

A: While this model is not computerized, its automatic and semi-automatic grades allow for precise control over sanding operations. Users benefit from reliable, repeatable results without the complexity of advanced digital systems, which can simplify operation and maintenance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plywood Sander Machines Category

Hardwood Calibrating & Sanding Machine

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Dimension (L*W*H) : 4200*2050*1900 Millimeter (mm)

Computerized : Yes

Warranty : Yes

Color : Multicolor

Heavy Duty Both Side Sanding Machine

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Dimension (L*W*H) : 2250x3350x2700 Millimeter (mm)

Computerized : No

Warranty : Yes

Color : Multicolor

Single Combi Head Sanding Machine

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Dimension (L*W*H) : 2150x2240x2200 Millimeter (mm)

Computerized : No

Warranty : Yes

Color : Multicolor

Triple Head Calibrating And Sanding Machine

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Dimension (L*W*H) : 3100x2240x2300 Millimeter (mm)

Computerized : No

Warranty : Yes

Color : Multicolor

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS