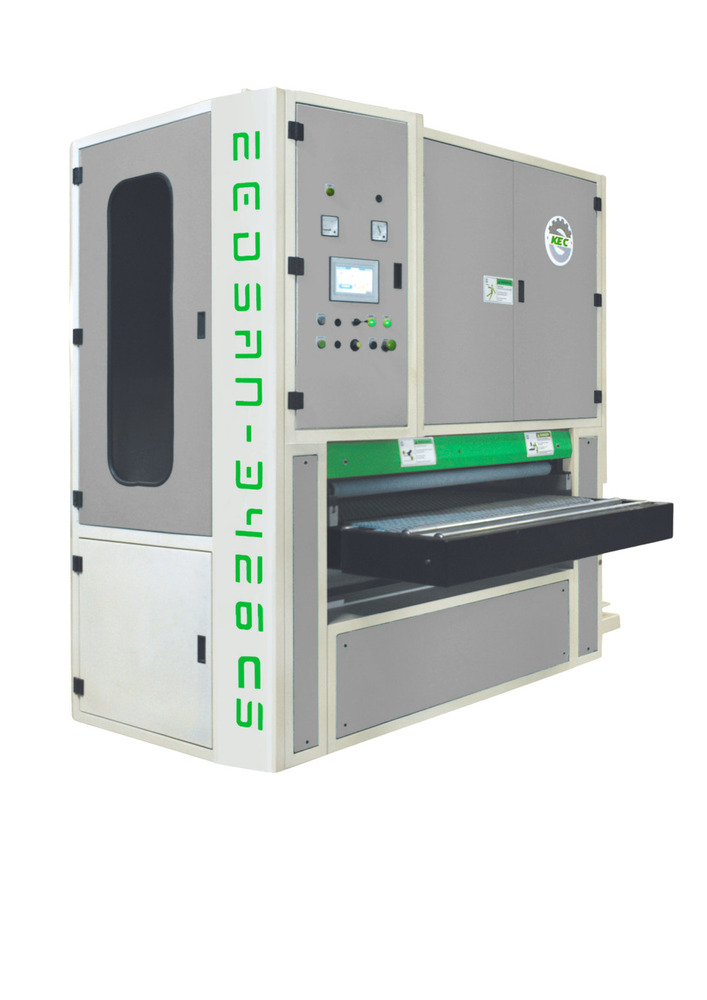

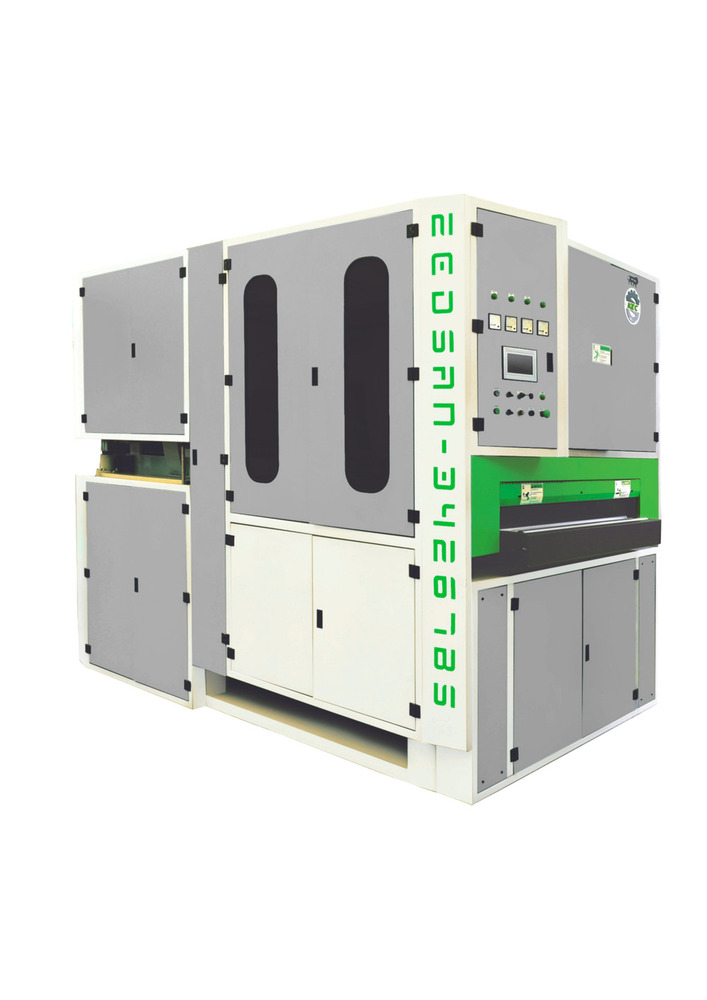

Single Combi Head Sanding Machine

Single Combi Head Sanding Machine Specification

- Type

- Single Combi Head Sanding Machine

- Material

- Mild Steel

- Computerized

- No

- Automatic Grade

- Automatic

- Power

- 20 Horsepower (HP)

- Voltage

- 240 Volt (v)

- Color

- Multicolor

- Warranty

- Yes

Single Combi Head Sanding Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 2 Units Per Month

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

- Certifications

- An ISO 9001:2015 certified

About Single Combi Head Sanding Machine

This model is specially designed for Veneer Faced Flush Door Units and small plywood units. The combination of roller and pad makes this machine very useful while keeping the machine as well as operational cost low.This machine provides different sanding results by different settings-

- Sanding by only rollers

- Sanding by only an air-cushioned pad

- Sanding by both

Exceptional Power and Efficiency

Equipped with a 20 horsepower electric motor, this sanding machine ensures superior performance for demanding industrial tasks. Its semi-automatic and automatic grade operation streamlines sanding, delivering consistent results and reducing manual effort.

Reliable Construction and Design

Fabricated from mild steel, the machine guarantees long-term durability and dependable operation. The vertical design facilitates efficient use of workspace, and the multicolor green-white finish adds aesthetic appeal and easy identification on the factory floor.

Suitable for Wide Industrial Use

Manufactured, supplied, and exported in India, this machine addresses the needs of various sectors with its comprehensive specifications. The sizable dimensions and weight support heavy-duty applications, making it an ideal solution for mass production environments.

FAQ's of Single Combi Head Sanding Machine:

Q: How does the Single Combi Head Sanding Machine operate in a semi-automatic mode?

A: The machine uses a combination of automated components and operator inputs to streamline the sanding process. Material is fed and processed vertically, while controls allow users to customize functions, balancing automation with manual adjustments for efficiency.Q: What are the main benefits of using a 20 HP electric-powered sanding machine?

A: Higher horsepower enables faster and more thorough sanding, supporting consistent quality over large batches while improving productivity and reducing downtime compared to machines with lower power ratings.Q: When is this sanding machine most suitable for use in manufacturing?

A: This machine is ideal during high-volume production cycles, where efficient finishing and reliable operation are necessary to maintain output and meet industrial demands.Q: Where can the Single Combi Head Sanding Machine be installed?

A: The vertical design and specified dimensions (2150x2240x2200 mm) make it suitable for installation in manufacturing plants, workshops, and large-scale production facilities that can accommodate its footprint and weight.Q: What is the process for maintaining this sanding machine?

A: Routine maintenance involves periodic inspection of electrical components, cleaning internal mechanisms, lubricating moving parts, and replacing worn-out sanding heads to ensure optimal performance.Q: How does the warranty benefit buyers?

A: Buyers receive a one-year warranty, which covers manufacturing defects or operational failures, providing peace of mind and assurance of after-sales support from the manufacturer, supplier, or exporter.Q: What materials can the Single Combi Head Sanding Machine process?

A: Primarily designed for materials compatible with mild steel machinery, the sanding machine is suitable for various wood, metal, and composite products, provided they match the industrial specifications of the unit.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plywood Sander Machines Category

Hardwood Calibrating & Sanding Machine

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : 4200*2050*1900 Millimeter (mm)

Warranty : Yes

Color : Multicolor

Computerized : Yes

Automatic Grade : Automatic

Heavy Duty Both Side Sanding Machine

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : 2250x3350x2700 Millimeter (mm)

Warranty : Yes

Color : Multicolor

Computerized : No

Automatic Grade : Automatic

Heavy Duty Laminate Sanding Machine

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : 1500x2840x2300 Millimeter (mm)

Warranty : Yes

Color : Multicolor

Computerized : No

Automatic Grade : Automatic

Triple Head Calibrating And Sanding Machine

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : 3100x2240x2300 Millimeter (mm)

Warranty : Yes

Color : Multicolor

Computerized : No

Automatic Grade : Automatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free