DD Saw Automatic Edge Cutting Machine (With Motion Controller)

Price 2300000.0 INR/ Piece

MOQ : 1 Piece

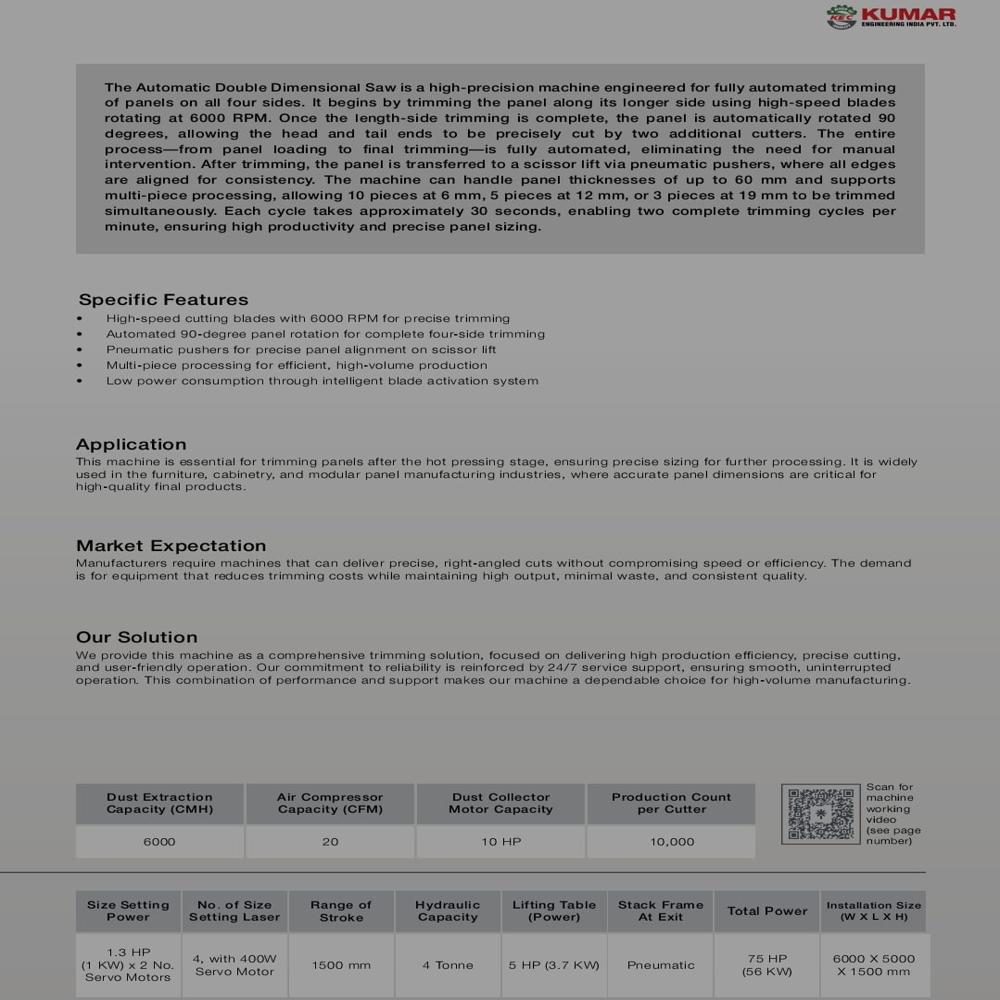

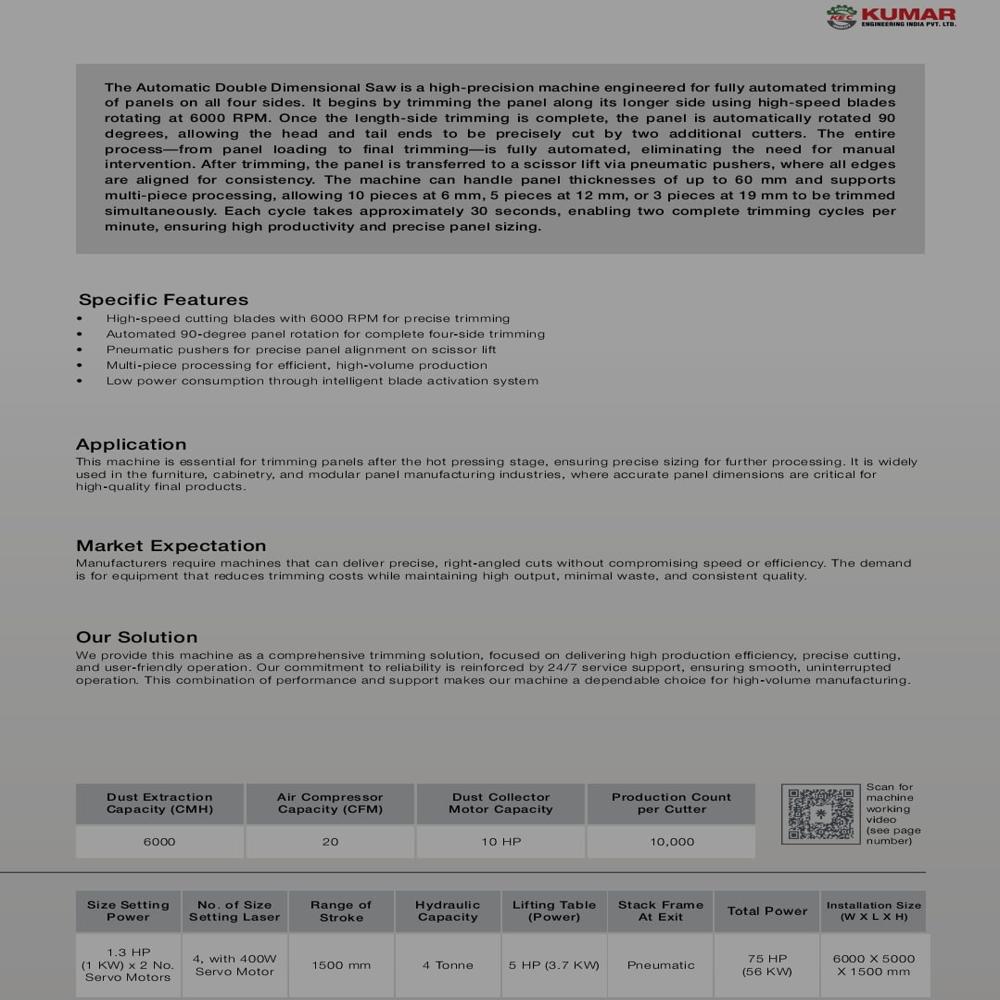

DD Saw Automatic Edge Cutting Machine (With Motion Controller) Specification

- Product Type

- Woodworking Machine

- Machine Type

- Saw

- Machine Style

- Horizontal

- Capacity

- 120 Pcs/hr

- Voltage

- 75 Horsepower (HP)

- Automation

- Automatic

- Motor

- 6

- Speed

- 6000 RPM

- Dimension (L*W*H)

- 5000x6000x1500 Millimeter (mm)

- Weight

- 2900 Kilograms (kg)

- Color

- green-white

- Warranty

- 1 year

DD Saw Automatic Edge Cutting Machine (With Motion Controller) Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- sampla

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 12 Pieces Per Month

- Delivery Time

- 60 Days

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- sand and water proof solution pakaging

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- An ISO 9001:2015 certified

About DD Saw Automatic Edge Cutting Machine (With Motion Controller)

Working features of this machine are as follows-- Plywood is to be loaded at the input side. It will further be carried away to the output side through dynamic design and hi-tech automation.

- The plywood is tightly held through pneumatic clamps.

- Longitudinal table carries the plywood through an extra high-speed cutter, having 6000 rpm speed, built exclusively by Kumar Engineering Co.

- After cutting it width-wise, the plywood is moved to the right angle of its initial motion, and then, high-speed length-wise cutting starts.

- Finally the bunch of sheets is auto stacked on the scissor lift.

Precision and Efficiency

This horizontal saw machine delivers high-speed edge cutting with uniform accuracy, capable of handling up to 120 pieces per hour. Its motion controller automates the process, minimizing manual involvement and ensuring consistent results for manufacturers and suppliers.

Robust Design and Construction

The DD Saw Automatic Edge Cutting Machine features a sturdy build, measuring 5000x6000x1500 mm and weighing 2900 kg. This robust design ensures stability during operation, reducing vibrations and enhancing safety for operators in industrial settings.

Versatile Applications

Engineered for various industrial materials, this saw machine is suitable for manufacturers, exporters, and traders across India looking for reliable and fast edge-cutting solutions. Its automated features boost productivity, making it ideal for large-scale production environments.

FAQ's of DD Saw Automatic Edge Cutting Machine (With Motion Controller):

Q: How does the motion controller enhance the operation of the DD Saw Automatic Edge Cutting Machine?

A: The motion controller automates the cutting process, enabling precise edge cutting and consistent operation. It significantly reduces manual input, improves accuracy, and increases productivity while ensuring safety during high-speed operations.Q: What materials can be processed with this edge cutting machine?

A: The DD Saw Automatic Edge Cutting Machine is designed to handle a range of industrial materials. Its robust construction and high-speed cutting capability make it suitable for applications in manufacturing, export, and supply industries.Q: When should the machine be serviced to ensure optimal performance?

A: Regular servicing is recommended, preferably after every few months of continuous operation or as indicated by the manufacturer in the user manual, to maintain peak efficiency and prevent unexpected breakdowns.Q: Where can this machine be installed for industrial use?

A: Due to its dimensions and weight, the machine is best suited for installation in spacious industrial facilities or manufacturing plants in India. It should be placed on a level, secure surface to support its robust build and stable operation.Q: What is the process for edge cutting with this automatic saw machine?

A: The process involves feeding materials into the machine, where the motion controller automates the cutting sequence. The machine precisely trims edges at 6000 RPM, efficiently handling up to 120 pieces an hour with minimal operator intervention.Q: How can users benefit from the automatic and high-capacity features of the machine?

A: Automatic operation and high processing capacity significantly enhance productivity, reduce labor costs, and ensure consistent quality. These features make the DD Saw Automatic Edge Cutting Machine ideal for businesses aiming for scalability and efficiency in edge trimming tasks.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Plywood Machinery Category

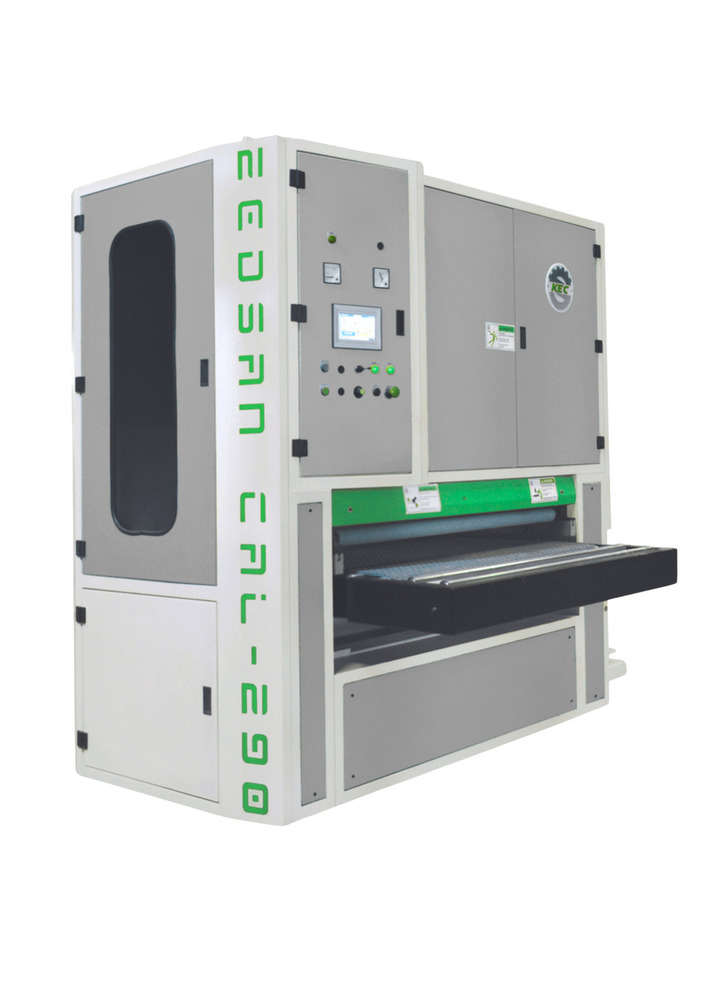

Single Head Calibrating Machine

Minimum Order Quantity : 1 Unit

Color : GreenWhite

Dimension (L*W*H) : 2150x2240x2300 Millimeter (mm)

Automation : Semi Automatic

Weight : 3000 Kilograms (kg)

Machine Style : Vertical

Heavy Duty Both Side Calibrating Machine

Minimum Order Quantity : 1 Unit

Color : GreenWhite

Dimension (L*W*H) : 1500x2440x2850 Millimeter (mm)

Automation : Semi Automatic

Weight : 9500 Kilograms (kg)

Machine Style : Vertical

Double Head Both Side Brushing Machine

Minimum Order Quantity : 1 Unit

Color : GreenWhite

Dimension (L*W*H) : 1800x1700x1950 Millimeter (mm)

Automation : Semi Automatic

Weight : 2200 Kilograms (kg)

Machine Style : Vertical

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free