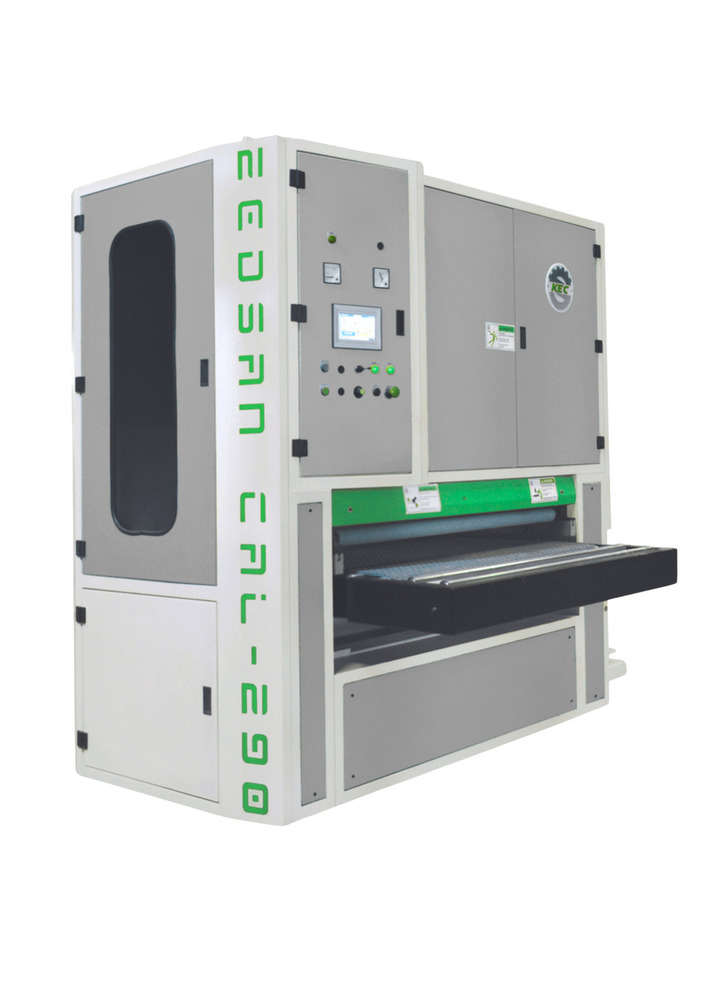

Double Head Both Side Brushing Machine

Double Head Both Side Brushing Machine Specification

- Product Type

- Woodworking Machine

- Machine Type

- Other

- Machine Style

- Vertical

- Power

- Electric

- Automation

- Semi Automatic

- Dimension (L*W*H)

- 1800x1700x1950 Millimeter (mm)

- Weight

- 2200 Kilograms (kg)

- Color

- Green-White

- Warranty

- 1 year

Double Head Both Side Brushing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 2 Units Per Month

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

- Certifications

- An ISO 9001:2015 certified

About Double Head Both Side Brushing Machine

This is featured with both side sanding in one pass, displaying Ampere consumed by individual brush. The thickness adjustment is carried out by all corner mounting jacks and digital display of ply thickness.

The brushing machine is fully capable to deliver the ultimate sanding results without any color fading.

High-Performance Semi-Automatic Brushing

The Double Head Both Side Brushing Machine streamlines industrial brushing processes, thanks to its vertical design and powerful electric operation. Its semi-automatic mechanism ensures consistent and uniform results, making it a practical solution for both medium and large-scale operations. With energy efficiency and easy-to-use controls, businesses experience improved productivity and reduced manual effort.

Robust Construction and Dimensions

Engineered for demanding industrial environments, this machine features a durable construction with a weight of 2200 kg and dimensions of 1800x1700x1950 mm. Its green-white aesthetic and vertical machine style allow for space-efficient installation. The sturdy build ensures longevity and reliable performance even in high-volume operations.

Reliable Indian Manufacturing and Support

Proudly manufactured in India, this brushing machine caters to exporters, suppliers, manufacturers, and traders. Quality assurance is guaranteed through a 1-year warranty and dedicated after-sales support, offering peace of mind and value for your investment.

FAQs of Double Head Both Side Brushing Machine:

Q: How does the Double Head Both Side Brushing Machine operate?

A: This machine operates on electric power and uses a double-sided brushing mechanism to clean or polish materials on both sides simultaneously. Its semi-automatic controls simplify operation, requiring minimal manual intervention.Q: What types of materials can be processed with this brushing machine?

A: The Double Head Both Side Brushing Machine is versatile and suitable for a wide range of industrial materials, including metal, wood, and plastic components that require surface cleaning or polishing.Q: When should this machine be used in the production process?

A: It is recommended to use this machine after primary shaping or cutting processes, where thorough cleaning or polishing is needed before further finishing or assembly.Q: Where is this machine manufactured and available for distribution?

A: This machine is manufactured in India and supplied by exporters, manufacturers, traders, and suppliers for domestic as well as international markets.Q: What are the main benefits of using a semi-automatic vertical brushing machine?

A: Benefits include increased production efficiency, consistent surface finishing, ease of operation, and reduced manual labor, all supported by robust construction and a 1-year warranty.Q: What is the installation process for this brushing machine?

A: Installation is straightforward due to its vertical and compact design. Basic setup requires placement on a stable floor space, electrical connection, and minor initial adjustments, which are typically supported by the manufacturer.Q: How can users maximize the lifespan of the Double Head Brushing Machine?

A: Regular cleaning, routine maintenance, and following the manufacturers operation guidelines will help ensure the machine operates efficiently and lasts throughout its warranty and beyond.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plywood Machinery Category

DD Saw Automatic Edge Cutting Machine (With Motion Controller)

Minimum Order Quantity : 1 Piece

Weight : 2900 Kilograms (kg)

Warranty : 1 year

Automation : Automatic

Machine Style : Horizontal

Color : greenwhite

Single Head Calibrating Machine

Minimum Order Quantity : 1 Unit

Weight : 3000 Kilograms (kg)

Warranty : 1 year

Automation : Semi Automatic

Machine Style : Vertical

Color : GreenWhite

Heavy Duty Both Side Calibrating Machine

Minimum Order Quantity : 1 Unit

Weight : 9500 Kilograms (kg)

Warranty : 1 year

Automation : Semi Automatic

Machine Style : Vertical

Color : GreenWhite

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free