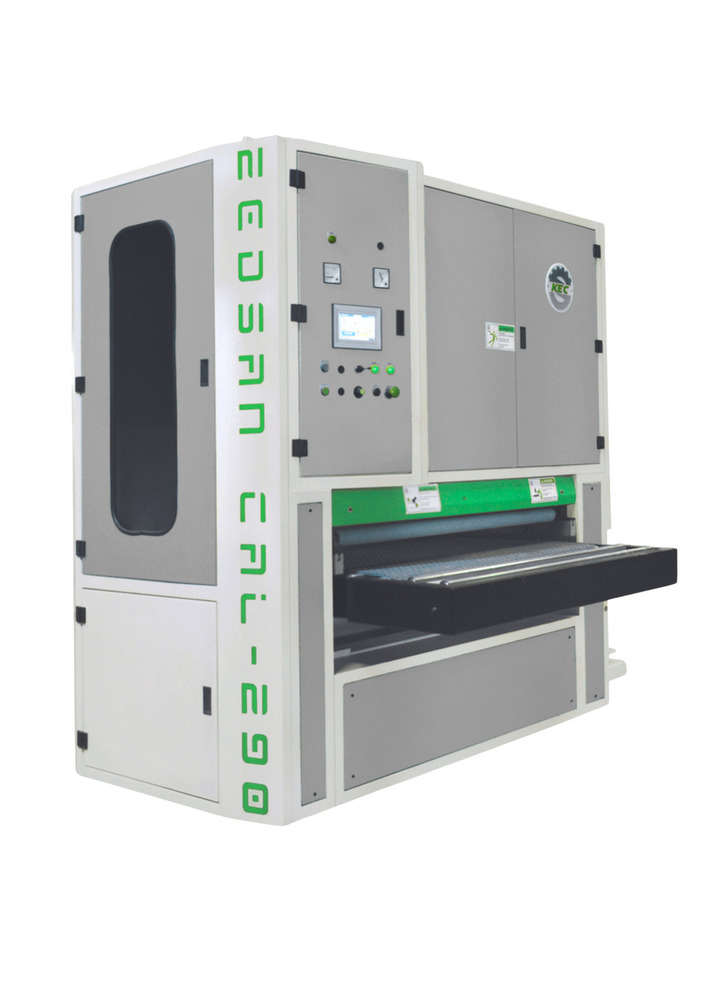

Heavy Duty Both Side Calibrating Machine

Heavy Duty Both Side Calibrating Machine Specification

- Product Type

- Woodworking Machine

- Machine Type

- Other

- Machine Style

- Vertical

- Power

- Electric

- Automation

- Semi Automatic

- Dimension (L*W*H)

- 1500x2440x2850 Millimeter (mm)

- Weight

- 9500 Kilograms (kg)

- Color

- Green-White

- Warranty

- 1 year

Heavy Duty Both Side Calibrating Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 2 Units Per Month

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

- Certifications

- An ISO 9001:2015 certified company

About Heavy Duty Both Side Calibrating Machine

This calibrator is a must need for producing the best quality to become listed amongst established branded plywood companies.

Robust Vertical Calibration Technology

Equipped with dual-side calibrating features, this heavy-duty machine delivers uniform thickness across wood and panels. Its vertical mechanism not only saves floor space but also enhances accuracy by minimizing deviation during operation. Suitable for intense industrial environments, it ensures longevity and steadfast reliability with each use.

Ideal for Industrial Scale Operations

With an impressive weight of 9500 kg and ample working dimensions, this calibrating machine is engineered for continuous, high-volume tasks. Its semi-automatic function allows for reduced manual intervention while maintaining operator control, maximizing productivity for exporters and manufacturers across India.

Comprehensive Support and Warranty

The machine comes with a one-year warranty, providing peace of mind and technical reassurance. As a product supplied and exported by trusted Indian manufacturers and traders, clients benefit from robust after-sales service and local expertise to support their production needs.

FAQs of Heavy Duty Both Side Calibrating Machine:

Q: How does the Heavy Duty Both Side Calibrating Machine operate?

A: This machine employs a semi-automatic vertical mechanism that precisely calibrates both sides of a panel or wood surface, using electric power to ensure consistent results and efficient throughput.Q: What are the key benefits of using this calibrating machine?

A: Key benefits include high calibration accuracy, robust construction for industrial use, minimized manual labor through semi-automation, and a vertical design that optimizes workspace and reduces operational footprint.Q: When should this machine be considered for use in production?

A: Use this calibrating machine when your operation requires rapid, precise, and uniform thickness calibration on both sides of large panels or wood, particularly in high-volume manufacturing environments.Q: Where is the machine commonly utilized?

A: It is widely used within factories, large-scale manufacturing units, and export-focused facilities across Indiaespecially where both surface precision and output consistency are critical.Q: What is the process for installing and starting up the machine?

A: Installation involves placing the 9500 kg machine securely on your factory floor, connecting it to an electric power supply, and following the manufacturers setup protocol. Comprehensive guidelines and support are provided to ensure a seamless start-up.Q: How does the one-year warranty benefit users?

A: The one-year warranty covers manufacturing defects and provides access to maintenance support, ensuring reliable performance and minimizing downtime during the initial period of operation.Q: How can exporters, manufacturers, suppliers, or traders in India purchase the machine?

A: This calibrating machine can be sourced directly from reputable exporters, manufacturers, suppliers, and traders across India, ensuring smooth transaction processes and local after-sales support.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plywood Machinery Category

DD Saw Automatic Edge Cutting Machine (With Motion Controller)

Minimum Order Quantity : 1 Piece

Product Type : Woodworking Machine

Weight : 2900 Kilograms (kg)

Dimension (L*W*H) : 5000x6000x1500 Millimeter (mm)

Machine Type : Saw

Warranty : 1 year

Double Head Both Side Brushing Machine

Minimum Order Quantity : 1 Unit

Product Type : Woodworking Machine

Weight : 2200 Kilograms (kg)

Dimension (L*W*H) : 1800x1700x1950 Millimeter (mm)

Machine Type : Other

Warranty : 1 year

Single Head Calibrating Machine

Minimum Order Quantity : 1 Unit

Product Type : Woodworking Machine

Weight : 3000 Kilograms (kg)

Dimension (L*W*H) : 2150x2240x2300 Millimeter (mm)

Machine Type : Other

Warranty : 1 year

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS