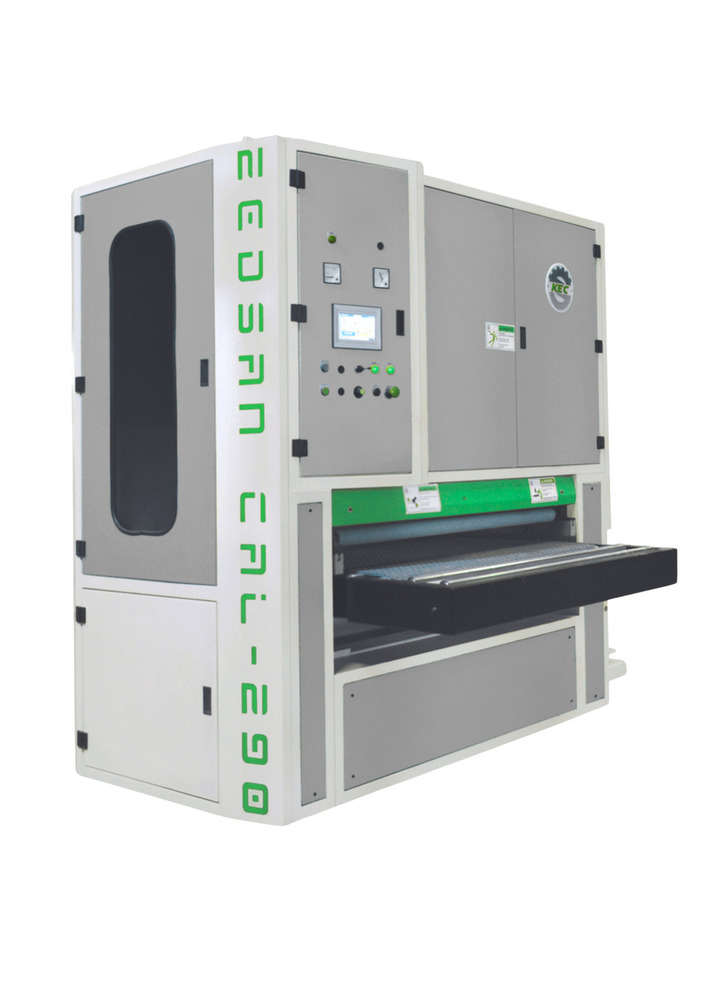

Single Head Calibrating Machine

Single Head Calibrating Machine Specification

- Product Type

- Woodworking Machine

- Machine Type

- Other

- Machine Style

- Vertical

- Power

- Electric

- Automation

- Semi Automatic

- Dimension (L*W*H)

- 2150x2240x2300 Millimeter (mm)

- Weight

- 3000 Kilograms (kg)

- Color

- Green-White

- Warranty

- 1 year

Single Head Calibrating Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 2 Units Per Month

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

- Certifications

- An ISO 9001:2015 certified

About Single Head Calibrating Machine

Single Head Calibrating machine is developed to produce a uniform thickness variation between 0.05 to 0.15 mm.We, as an innovating company in this field, created an ultimate design in Calibrating Machine with combinations of unique features, such as-

- Highly accurate calibration

- Good speed of production

- Lowest electricity consumption

- High number of sheet output per sanding belt

- User friendly in Maintenance

- Smooth production.

Advanced Vertical Design for Efficient Calibration

Engineered with a vertical layout, the Single Head Calibrating Machine optimizes space and workflow in industrial facilities. This design supports a seamless calibration process, resulting in consistent output quality. The robust build ensures stability during operation, making it an ideal choice for manufacturers aiming for precision and reliability in their production lines.

Automation Enhances Productivity

Featuring semi-automatic control, this calibrating machine streamlines operations and reduces manual intervention. The automation system ensures faster cycle times, standardized calibration, and minimizes human error. This translates into higher throughput and improved consistency, benefiting industries that demand both quantity and quality in their calibrated products.

FAQs of Single Head Calibrating Machine:

Q: How does the Single Head Calibrating Machine with Automation operate?

A: This calibrating machine uses electric power and features a semi-automatic system, allowing operators to perform calibration tasks efficiently with reduced manual effort. Its vertical design facilitates straightforward processing and easy integration into existing workflows.Q: What are the primary benefits of using this machine in a manufacturing facility?

A: The main advantages include high precision in calibration, increased productivity due to automated features, and consistent output quality. With its sturdy construction and advanced automation, it supports reliable and efficient operation for manufacturers, suppliers, and traders.Q: When should routine maintenance be performed on this calibrating machine?

A: Routine maintenance is recommended every three to six months, depending on usage intensity, to ensure optimal performance and longevity. The 1-year warranty also covers necessary repairs and servicing within this period.Q: Where can this vertical calibrating machine be installed?

A: Given its dimensions (2150x2240x2300 mm) and vertical build, it is suitable for spacious industrial settings, manufacturing plants, and calibration workshops across India. Proper installation space is essential for safe and efficient operation.Q: What is the process for calibrating materials using this machine?

A: Materials are loaded and positioned on the machine, after which the semi-automatic system manages the calibration process. The operator oversees cycle initiation and monitors outcome precision, ensuring each item meets required standards.Q: How does automation improve the usage of this calibrating machine?

A: Automation minimizes manual handling, increases calibration speed, and promotes consistent results, which is ideal for high-volume operations requiring accuracy and repeatability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plywood Machinery Category

DD Saw Automatic Edge Cutting Machine (With Motion Controller)

Minimum Order Quantity : 1 Piece

Product Type : Woodworking Machine

Warranty : 1 year

Machine Type : Saw

Dimension (L*W*H) : 5000x6000x1500 Millimeter (mm)

Machine Style : Horizontal

Double Head Both Side Brushing Machine

Minimum Order Quantity : 1 Unit

Product Type : Woodworking Machine

Warranty : 1 year

Machine Type : Other

Dimension (L*W*H) : 1800x1700x1950 Millimeter (mm)

Machine Style : Vertical

Heavy Duty Both Side Calibrating Machine

Minimum Order Quantity : 1 Unit

Product Type : Woodworking Machine

Warranty : 1 year

Machine Type : Other

Dimension (L*W*H) : 1500x2440x2850 Millimeter (mm)

Machine Style : Vertical

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free